Window glide ordering

Window glide ordering

Like putting disc brakes on a Mark II most people have no idea how good new brakes are with properly arced shoes to fit the drum. New guides solve problems and make the best of what you have to work with.

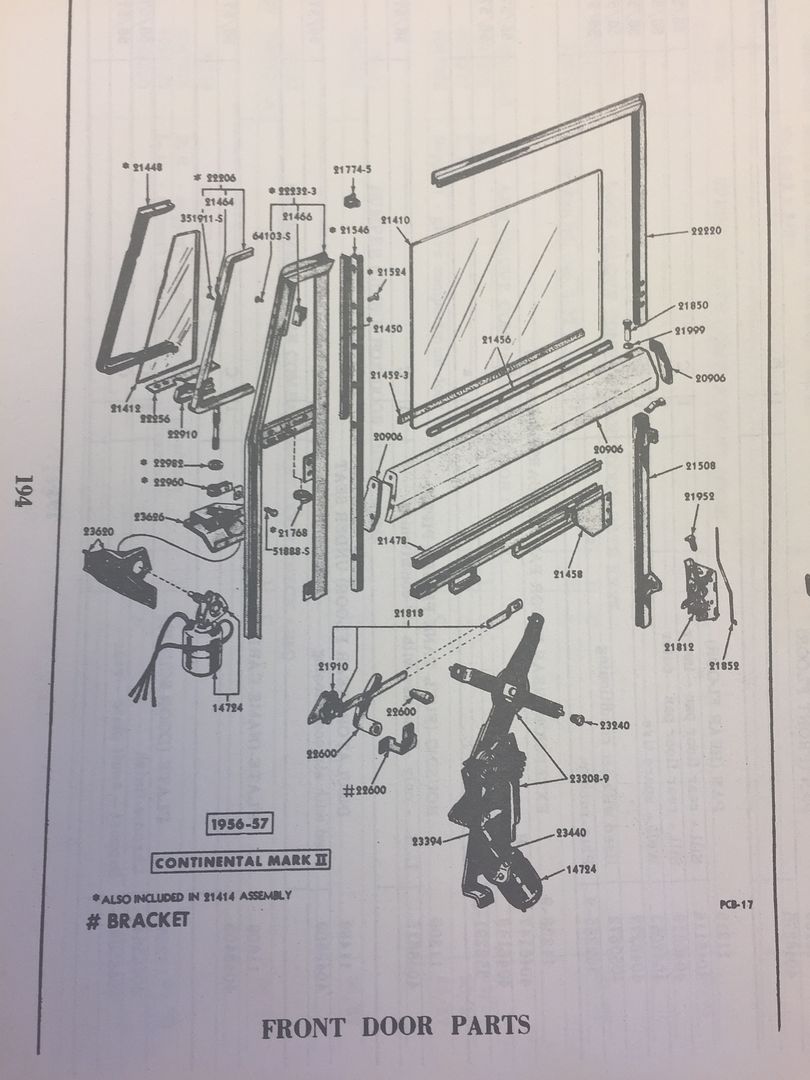

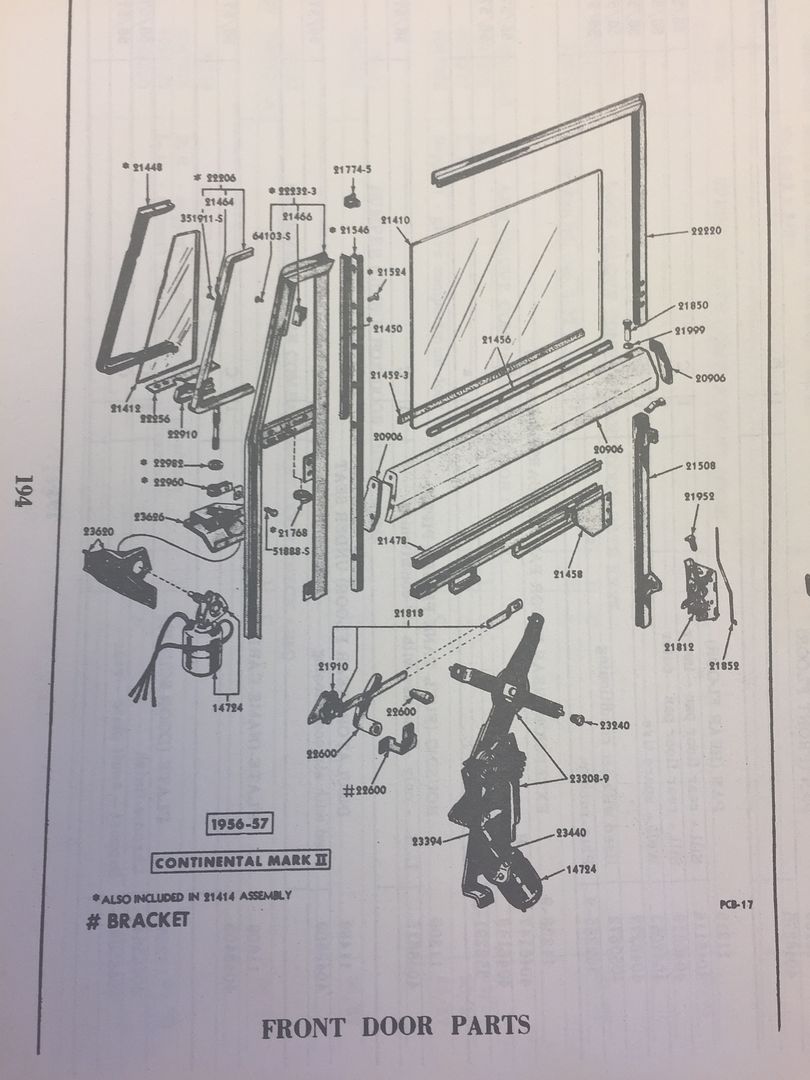

It probably would help if you knew what was inside your door.

The plastic "rollers", which are actually glides or guides, as they were never meant to roll, and really don't in the application. They are only movable pivot points for the changing geometry of the window lift mechanism. Two guides lift the window and keep it level while a third guide acts as a pivot point for equally lifting the window. The guides only move horizontally. Each Ford window assembly in this era uses 3 of these.

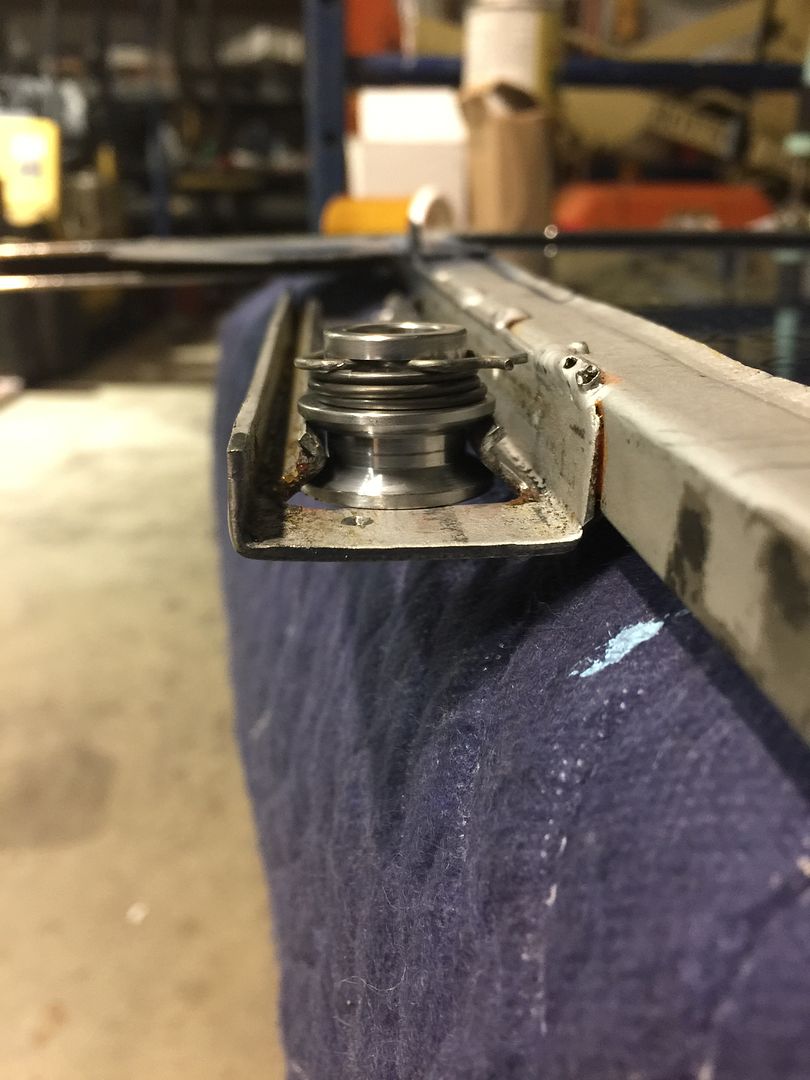

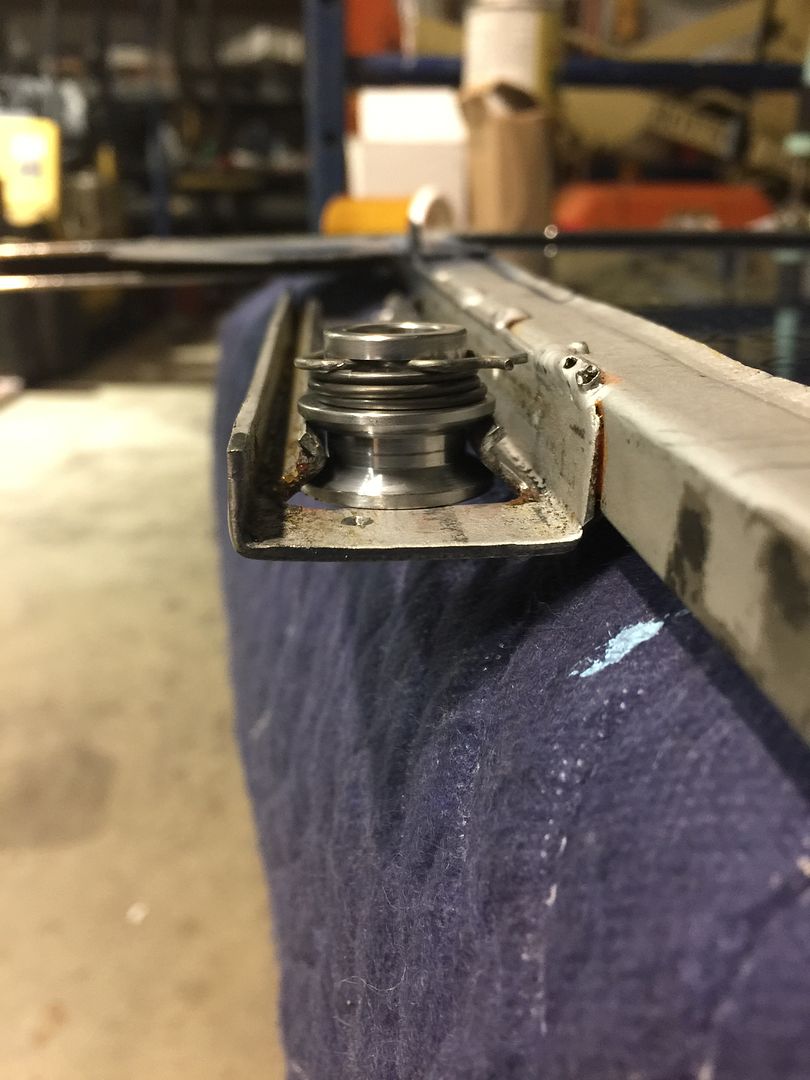

The track they ride in is .625", or 5/8"wide. Due to them not rotating plastic and sheet-metal replacement units wear out quickly. Plastic that doesn't roll will wear out 100 times as fast as dirt acts as an abrasive and wears away the plastic quickly. Also, the plastic units have stamped sheet metal parts that quickly lose their thin galvanizing and rust away. The object is to have them make as little contact as possible, reducing friction. This is one of my new guides in fresh waterproof water-pump grease. Note how thin the contact line in the grease is.

This is the way they slip onto the guide rail. The guide slides into the twin rails by compressing the spring, putting metal on both sides of the guide. With the spring-loaded metal pushing on both sides of the rail equally gives the guide had equal friction, keeping its orientation. When this happens the guide becomes oblong, allowing for catchy movement as your window rises. This appears as your window wanting to pull out of the vertical track on the vent window assembly as it rises.

These are your 3 basic choices. Someone is making them in brass, but the originals are hard metal and I fear brass would wear out as fast as plastic.

The left spool is an OEM I found on low-mileage cars. I'm not sure they are stainless, but they don't rust. They are hard, but not hardened. I found no wear on any of them, but they came from 20,000 mile cars. You can see how torn up the plastic one is on only a month's use. It has a fatal flaw in that it has no meat in the center and they simply folded over and pulled through the track. Pure junk available from all the venders. The one on the right might be an OEM Ford unit. It's just galvanized sheet metal. Every one of these was worn oblong where the ramp meets the shaft. Rotating the glide made the slop disappear. Where they had worn through the galvanizing there was rust.

The springs steel clips should be reused as the new ones have a slightly different shape. The old ones should be been bent until the tips touch, before installation. The old coil springs should be re-used. I am looking for replacements. The new ones come with stronger coil springs because there no substance to the sheet metal guide.

This is why the shape is important. The glide slides down a shaft with a groove in it that catches the spring tips to lock it in without tools.

The unbent clip on the left will not exert as much force to lock in the guide on the shaft. If you've ever had one pop off after you've reinstalled the door panel it doesn't get much more frustrating.

This is an important assembly tool. Use anything round that will fill the hole. If you don't the clip will get stuck in the inside hole. Using a shaft makes the clip slide over it and into position, every time.

A thing of beauty.

Here's the deal. I scrapped the first batch of 9. They were a struggle to get into the groove, but they fit.That was $315 that I'm writing up to prototype expenses. The second batch came in at $31.00 or $279 for 9. I asked for production numbers of 60 and 120 pieces and he lowered the production cost to $24 and $21.

While you can certainly re-use original guides just by cleaning and lubricating them, I believe all 3 guides should be new on a window as they will all drag on the track in the same manner.

The following pricing will be based on 3, 6 and 12 guide purchases. All prices exclude shipping. I'll likely have to charge sales tax and shipping. They are machined out of 410 stainless.

How about $35 each for 3, $30 each for 6 and $25 each for 12?

Both of the parts supplied are programmed into their CNC, ready to go. 3-week lead time. I have 6 to sell.

Please post if you are interested and if you know of a better solution.

Barry Wolk

Farmington Hills, MI

C5681126

Reply With Quote

Reply With Quote