Treadle-Vac

Treadle-Vac

How long were the Continental sleeve-valve Treadle-Vacs used? I'm told that it wasn't much past the build of the Introductory Units, but I don't know for sure, because they are often swapped out.

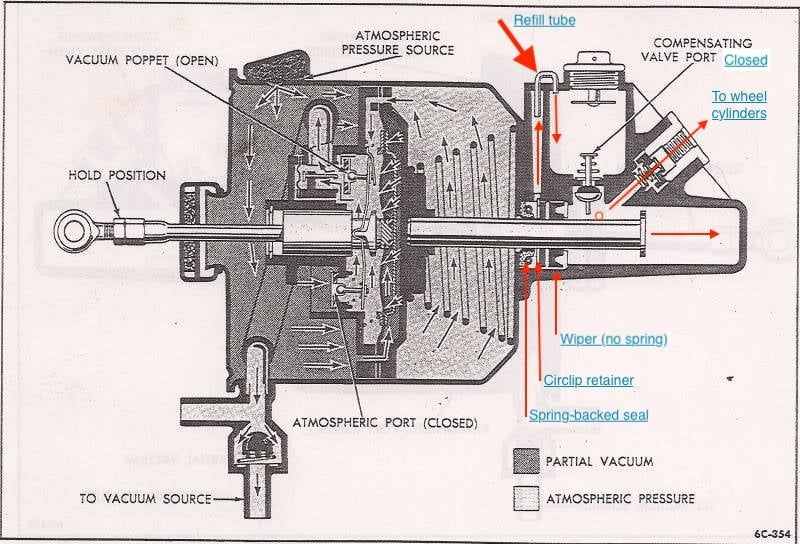

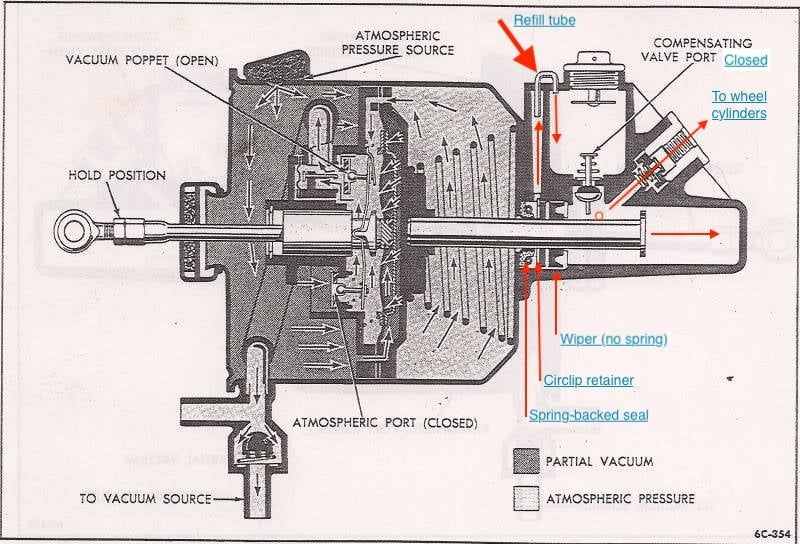

The 1957 Mark II I'm working on should have the poppet-style booster, but it has the sleeve-valve type. I'm told the poppet-style are quite "grabby" because they are a more positive seal unlike the constant vacuum leak of the sleeve-valve.

Maybe someone can confirm this. Was the Lincoln T-V fitted with the refill tube the Continental had? If it didn't, I believe whoever rebuilt this last didn't know the difference and fitted the Continental lid to a Lincoln master cylinder. On the Lincoln unit the hole in the casting appears to be filled in with an epoxy where the Continental casting has a passage hole drilled through to the ring between the shaft seals.

Due to this hole being sealed flush the pipe nub on the slanted cover had no place to go, so every time Al topped off his fluid it all wept out. Speaking of the cover, why was it not flat, like the one shown in the service manual? Every single Mark II reserve I look at has too much fluid in it, which seeps out the lowest part of the imperfect cork gasket. The cover is the dipstick.

I don't think this is seal damage. I believe that drip came from the soaked cork gasket between the master and booster. The seals look new. I think the fluid came from the lid seal, but I could be wrong.

I found the check valve off-center and leaking. The spring had been install with two rubber nubs inside the spring and two outside. He had no reserve vacuum. Has anyone used Plastidip tool handle restorer to redo the surface of the plunger?

Barry Wolk

Farmington Hills, MI

C5681126

Reply With Quote

Reply With Quote